Wheel nut hole wear is an expensive problem for fleets and owner-operators because wheel-offs cost in time and money; not to mention they can be a big safety concern.

Of course, it all starts with proper installation of wheels, with making sure wheel nuts are properly torqued. We go into detail on this in our Service Manual for Alcoa Wheels.

We recommend frequently inspecting your wheels for loose wheel nuts. A good time to carry out these inspections is during tyre changes, when you can get a good look at the entire wheel and check for cracks and corrosion, too.

Older wheels, especially, need more frequent checks.

If the wheel is loose, the bolt/stud holes can become elongated (egg-shaped).

If the wheel nuts are loose, you may break studs and/ or develop cracks at the stud holes.

Below are some maintenance tips for looking after your wheel nuts.

Maintaining Alcoa® Wheel Nuts to Avoid Wheel Nut Hole Wear

The Big Retro Fit Nut Myth

The biggest myth about retrofit nuts is that they can be used to locate the wheel. Retrofit nuts are not wheel locators.

Here’s what to look for when using retrofit nuts:

1. Make sure the wheel has a stud hole large enough to accommodate the nut shank.

2. Make sure the wheel is located on the hub. Remember: Retrofit nuts are not wheel locators.

3. If using a longer shanked retrofit nut, make sure it doesn’t bottom out on the end of the stud thus affecting clamping force.

You’ll need a retrofit nut (special sleeved nut) when you’re fitting alloy truck wheels to a truck that previously had steel wheels fitted.

This is due to the overall thickness of the mounting surface of the wheel being bigger.

The shank or sleeve of Alcoa® retrofit nuts extend right into the mounting holes of the wheel and connects with the shorter stud length so that it takes up the extra stud length to affect the correct clamping force.

Alcoa wheels have a 32mm stud hole diameter to accommodate the retro fit nuts.

NOTE: For the correct torque setting, please refer to your truck or trailer manufacturer’s operator manual.

Looking After Stud Holes

We recommend regular checking of stud holes for enlargement and elongation so that you catch damage in time and avoid costly wheel-offs.

Often a clue that wheel nuts are loose, is that you’ll see dirt streaks or rust radiating from stud holes.

WHAT TO LOOK FOR TO IDENTIFY LOOSE WHEEL NUTS:

Look for wallowed out or elongated ball seats on stud piloted wheels, which are signs your wheels are running loose.

On hub piloted wheels, look for elongated stud holes.

If you spot damaged ball seat contact areas (the stud hole looks egg-shaped instead of perfectly round), remove the wheel from service and scrap it.

Look for visible thread marks on the inside of the stud holes, which are also evidence that your wheels have loose wheel nuts.

Keeping Wheel Nuts Tight

We recommend you make sure wheel nuts stay tight by checking the torque, studs and nuts at regular service intervals.

A good practice is to check nuts and studs at the minimum at every tyre change to ensure they are in serviceable working condition.

If nuts require frequent tightening or studs break often, we recommend reviewing your hardware and mounting practices to ensure the correct procedures and setting guidelines are being followed.

DO’S AND DON’TS

- DO Tighten wheel nuts to their specified torque. This is extremely important.

- DON’T Under tighten wheel nuts, as this results in loose wheels which can damage wheels, studs and hubs, and can result in wheel loss.

- DON’T Overtighten wheel nuts, as this can damage studs, nuts and wheels and will also result in loose wheels.

- DO Make sure you are calibrating all torque wrenches, impact wrenches and any other tools for tightening wheel nuts to ensure the proper torque is applied.

For all the information you need to keep your hub piloted wheel nuts tight, refer to the Alcoa Wheels Service Manual.

Proper Torque Sequence for Hub Piloted Wheels

You will find information on the proper torque sequence in our Torque Settings article.

Always refer to the Owner’s Manual of your equipment for the correct torque settings.

Minimizing Corrosion When Maintaining Wheel Nuts

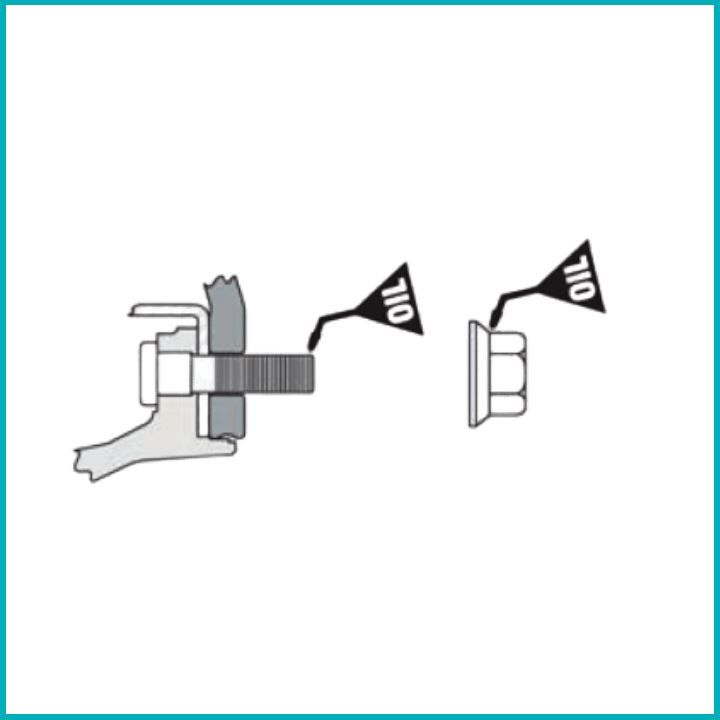

A tip for minimizing corrosion between the mating threading when putting wheel nuts on hub piloted wheels, is to apply two drops of oil to the point between the nut and the integrated washer and two drops of motor oil to the first two threads of the tip of each stud.

Alcoa Wheels recommend the following wheel nuts for use with Alcoa® alloy truck rims:

Did you know that chrome-plated wheel nuts with chrome plating on the surfaces that contact the wheel can cause reduced and inconsistent wheel clamping?

This can cause wheels to loosen and disengage from your heavy duty equipment and create a serious safety hazard.

We recommend using only Alcoa Wheels wheel nuts on Alcoa aluminum wheels.

Refer to either our US or European Alcoa Wheels Service Manuals for recommended Flange Nuts (Hub Piloted Wheels) and Cap Nuts (Stud Piloted Wheels).

Maintaining Alcoa® Wheel Nuts to Avoid Wheel Nut Hole Wear

Make Sure It’s An Alcoa® Wheel

To spec your wheels, ring ![]() 1800 955 191 to talk with our wheel experts, or fill out a contact form and we will reach out to you to answer your questions and discuss your specifications.

1800 955 191 to talk with our wheel experts, or fill out a contact form and we will reach out to you to answer your questions and discuss your specifications.