As we step into the new 2024, the enduring debate in the truck wheel industry persists—aluminium or steel wheels? This perennial topic sparks in-depth discussions among experts, exploring the nuances between these two metals and delving into their advantages, disadvantages, and manufacturing processes. As pioneers in aluminium wheel innovation, we confidently assert our preference for forged aluminium wheels, and here’s a comprehensive breakdown of why aluminium wheels prevail over steel. .

The Simple Solution: Lighter weight

Choosing lighter-weight forged aluminium wheels is the ultimate solution for enhancing overall fuel efficiency and, more crucially, reducing maintenance costs. Contrary to misconceptions, forged aluminium wheels are not akin to aluminium cans recycled through shredding. Their mechanical properties endow them with high yield strength and significant elongation, ensuring durability. As the industry emphasises low operating costs, the urgency for fleets to adopt solutions contributing to improved freight efficiency, reduced maintenance costs, and increased productivity has never been greater. Beyond being lighter than steel, forged aluminium wheels also boast superior strength and durability, increasing freight capacity and generating maintenance savings for heightened productivity and ultimately lower lifetime operating costs.

Fuel Efficiency and Weight Savings

When spec’ing wheels on new equipment, considering overall lifetime operating costs is paramount. Forged aluminium wheels facilitate quick and continuous payback through fuel savings and enhanced freight productivity, coupled with maintenance savings. Innovative technologies from wheel manufacturers contribute to increased weight loss, such as the significant reduction in wheel weight offered by forged aluminium wheels compared to their steel counterparts. See the last successfully tested fuel saving compared Aluminium wheel vs steel.

It’s a well-known fact that lighter trucks can legally carry more cargo. The latest Alcoa ULT36 Ultra One wheel, measuring 22.5″ x 8.25″ with a hub pilot and 285.75mm bolt circle, weighs only 16kg. This significant weight reduction enhances fuel efficiency. Forged aluminum wheels not only offer environmental benefits but also enable larger payloads, reducing the need for extra trips. Their infinite recyclability ensures they are never left in landfills.

Maintenance Advantages

Maintenance is crucial for fleet managers, especially concerning refurbishing, curbing damage, and tyre and brake life. Unlike steel wheels, aluminium wheels do not necessitate continuous refurbishing activities like rust removal, repainting, or touch-ups. Aluminium wheels, being unpainted, eliminate the need for spray paint and touch-ups. In harsh environments, where rust is a common issue for steel wheels, aluminium wheels offer a maintenance advantage by not requiring yearly tyre dismounting, painting, and remounting.

Forged aluminium wheel manufacturers often provide additional options for lowering operating and maintenance costs, including proprietary surface treatments integral to production. Alcoa DuraBright – advanced surface treatment ensures durability, preventing cracks, chips, or corrosion. Specially treated aluminium wheels do not require polishing. They are easy to clean with a simple soap and water scrub, contributing to lower maintenance costs and a longer-lasting, newer vehicle appearance.

The strength of forged aluminium wheels proves reliable even in the harshest environments, improving maintenance and extending equipment life. Additional surface treatments, such as those reducing rim flange wear, are advantageous for specific applications, such as heavy haul and shifting load scenarios.

Improved heat dissipation is another benefit, contributing to longer tyre and brake life. Aluminium’s superior heat dissipation, compared to steel, is particularly crucial in frequent stops and starts, as seen in refuse trucks. Aluminium wheels dissipate heat faster, preventing excessive wear on tires and brakes.

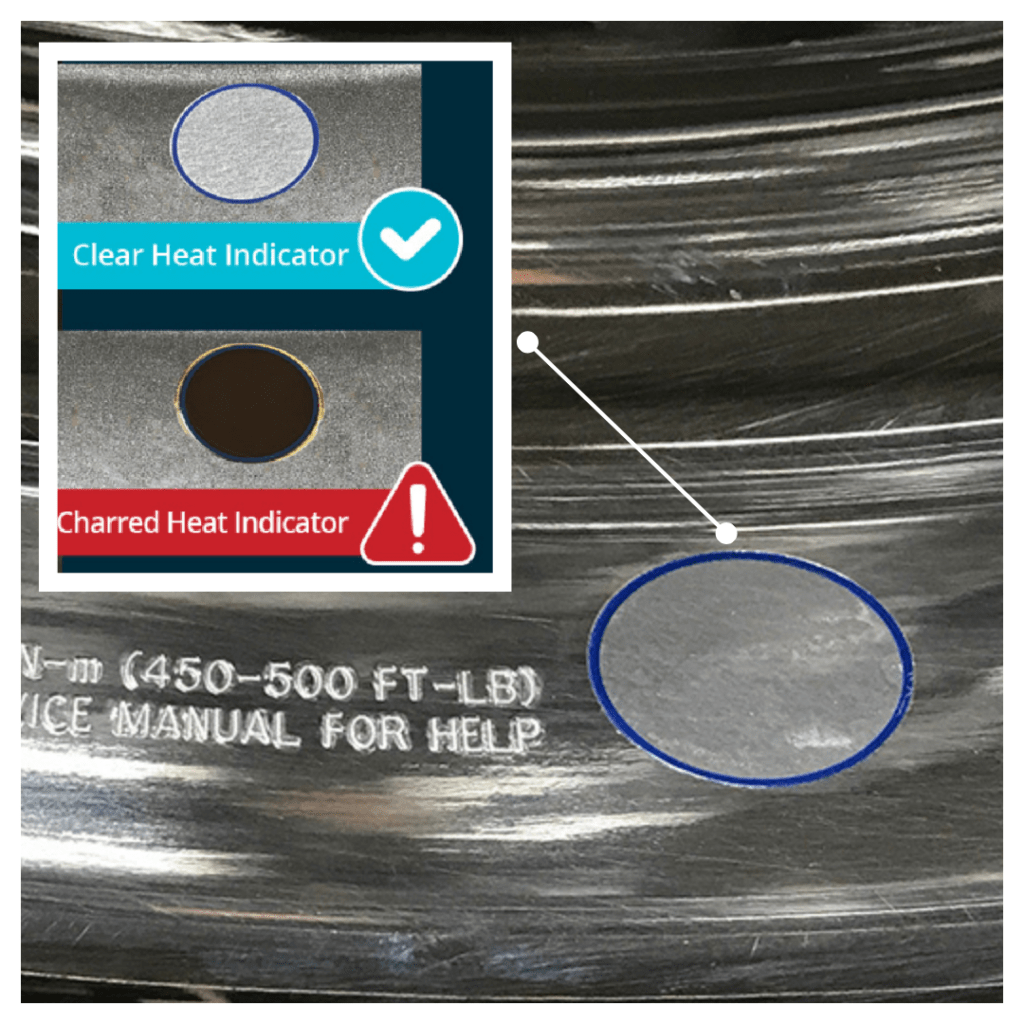

In instances of heat-related incidents, aluminium wheel manufacturers often incorporate heat indicator sensors on wheels to alert when excessive heat has passed through, ensuring timely maintenance.

Enhanced Image and a Smoother Ride

Forged aluminium wheels not only bring pride to fleets and operators but also offer a smoother ride. Being 100% CNC machined eliminates runout and vibrations, enhancing the overall comfort of the trip.

When making wheel choices, prioritizing value is critical. Forged aluminium wheels provide lifetime advantages over steel wheels. While steel wheels may be cheaper at purchase, their increasing maintenance requirements over time should be considered. The decision ultimately boils down to short-term versus long-term planning, navigating available choices to ensure value over the equipment’s lifespan.

For more information about truck and trailer wheels, contact Howmet Wheel Systems at 1800 955 191, email alcoawheels.sales@howmet.com, or visit alcoawheels.com.au. Stay updated by following Alcoa on: alcoawheelsaustralia