The prominent ‘lightest wheel in the market’ statement by Alcoa® Wheels has drawn in a lot of curiosity – and some great questions – from customers and other interested parties.

A statement like this isn’t said lightly, if you’ll pardon the pun. Alcoa Wheels were the very first forged aluminium wheel in the world, when in 1948 Aluminium company, Alcoa, using an alloy it had developed for the aerospace industry, invented the forged aluminium wheel.

In 1968, the Alcoa company set the industry standard again when it launched its 6061 alloy for forged aluminum wheels. Alcoa’s 6061 material provided a strong, durable alloy, resistant to corrosion that is used to this day by all major forged aluminum wheel manufacturers as the industry standard alloy.

Alcoa® Wheels have continually met increasing demands for lighter weight wheels, and by 2013 their design experts were engineering products 4.5kg lighter than wheels from 20 years before, using the same alloy.

Today, weighing in at just 18kg, the new Ultra ONE® Wheel is heralded as the lightest and strongest forged aluminium wheel in the world of commercial vehicles; manufactured from an exclusively patented alloy (6361) which is 17% stronger than the industry standard.

Here are the answers to 8 questions about the Ultra ONE® Wheel:

QUESTION 1: What does spec’ing the lightest wheel mean for my business?

A: In order to meet carbon emission regulations at truck OEM’s, fleets are switching to lighter-weight wheels more and more to offset the weight of technologies needed to remove air pollutants from diesel engine exhausts.

Lighter-weight, lower-maintenance wheels also help trucks improve fuel economy to help make up for rising fuel prices and move goods in a cleaner, more fuel-efficient way.

With the Australian Government extending the Instant Asset Write-off incentive recently, truck and trailer OEMs, together with owner-operators are taking advantage of being able to spec premium wheels like Alcoa® Wheels, and even up-spec to a Dura-Bright® finish, because they are able to make the best wheel investment decision comfortably and do it right, first time.

QUESTION 2: How do the numbers stack up when cost is a serious consideration for me?

A: The average forged aluminium 22.5” x 8.25” wheel weighs 23 kg, which is 25% heavier than the new Ultra ONE® Wheel. Put that into a payload calculator and you’ve got some serious savings over the lifetime of your equipment.

QUESTION 3: What applications are the new Ultra ONE® Wheels good for?

A: Because of the strength and durability of Alcoa® Wheels, they perform well in the harshest of conditions and are chosen by leaders in the mining operating industry, as well as for long haul applications, where payload and fuel efficiency are important considerations in the trailer build process.

The new Ultra ONE® Wheel is currently available in standard US fitment on 10-285, so you’ll see it on Tippers, Tankers, Skels and Tautliners – in fact, any trailer seeking to be light weight will benefit from this durable, light wheel that’s trusted by some of the biggest OEM’s in the world. Learn more about which applications Alcoa® Wheels suit.

The Dura-Bright® finish is widely used on the Ultra ONE® Wheel where maintenance down time is a cost factor to operators.

QUESTION 4: How does the new wheel compare to the previous version of the Alcoa® Ultra ONE® Wheel?

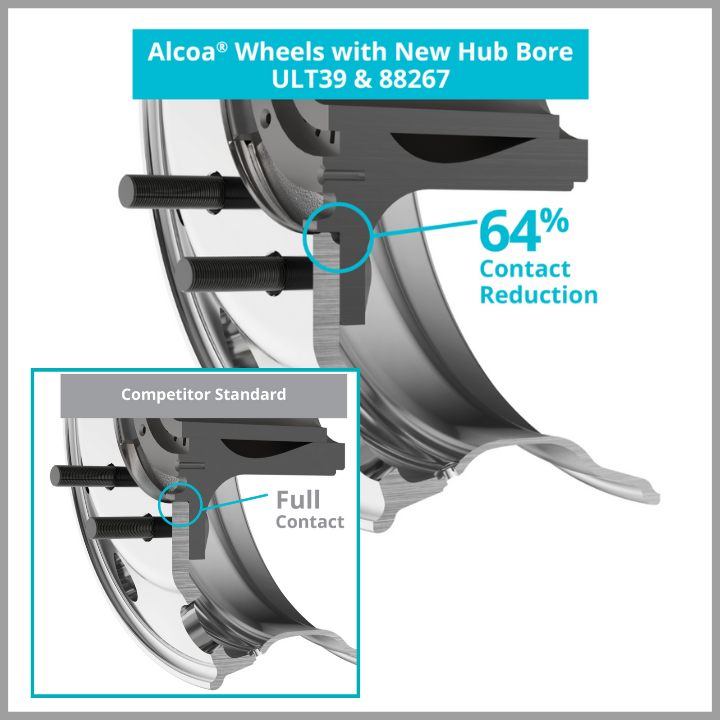

A: The new 18kg wheel is an improvement in important ways. Its new Hub Bore Groove Technology reduces the metal-to metal contact area between the wheel and the hub wheel end by half. This reduces the opportunity for corrosion to form, thus allowing for easier wheel removal during maintenance.

Aside from the Hub Bore Groove Technology, the exclusive to Alcoa® Wheels patented MagnaForce® Alloy is 17% stronger than the industry standard for forged aluminium wheels, which means that while the new Ultra ONE® wheel is 600grams lighter than the previous version, the load rating is the same at 3,355kg and payloads are thus improved further.

QUESTION 5: Does the new wheel look different to the previous Ultra ONE® wheel?

A: The wheel face, hand holes, and rim profile all look the same as the previous version, with minor changes not easily visible. The only visible change you will note is the new enhanced hub bore with less metal present to reduce contact with the wheel hub. Once mounted this hub groove will be hardly noticeable.

QUESTION 6: How will I know if I have the new Ultra ONE® wheel or the previous one?

A: The difference is in the part number. On the wheel roll stamp, you’ll see ULT39 in the part number, indicating the new 18kg wheel. The previous wheel part number began with ULTRA.

QUESTION 7: What finishes are offered with the Ultra ONE® Wheel?

A: This new wheel is offered in the same leading finish options: LvL ONE®, Mirror Polish and Dura-Bright®.

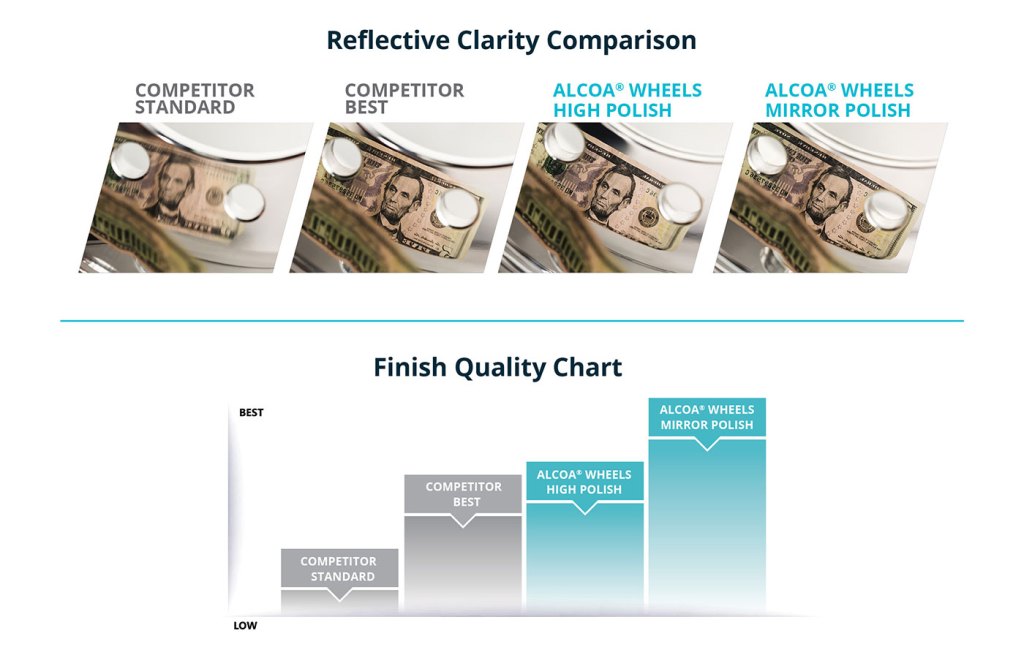

- LvL ONE® reflective finish and high gloss levels give the wheel an appearance 6 times brighter than that of competitor wheels.

- Mirror Polish is in the premium wheel finish exclusive to Alcoa® Wheels, with the highest level of gloss and reflectivity of any wheel on the market.

- Dura-Bright® surface treatment offers a consistent shine without the need to polish.

Compare the various Alcoa® Wheels finishes here.

The quality of Alcoa® Wheels finishes is evident in the ‘Reflective Clarity Comparison’ below, with the competitor best finish sitting far below the Alcoa® Wheels’ standard LvL One® finish.

QUESTION 8: Where can I inspect the Ultra ONE® wheel?

A: Call ![]() 1800 955 191 and talk to our wheel specialists. They will help you decide if the new Ultra ONE® Wheel is right for your equipment…and we’ll arrange to come out to you.

1800 955 191 and talk to our wheel specialists. They will help you decide if the new Ultra ONE® Wheel is right for your equipment…and we’ll arrange to come out to you.

Make Sure It’s An Alcoa® Wheel

Did you know that you can specify Alcoa® Wheels when buying a truck or trailer?

Ask for Alcoa® Wheels to be included in the quote. To spec your wheels, ring ![]() 1800 955 191 to talk with our wheel experts, or fill out a contact form and we will reach out to you to answer your questions and discuss your specifications.

1800 955 191 to talk with our wheel experts, or fill out a contact form and we will reach out to you to answer your questions and discuss your specifications.