Alcoa® Wheels, the global leader in aluminum wheel innovation, introduces two new products featuring revolutionary technology that reaffirms its position as the lightest aluminium truck wheel manufacturer in the industry the NEW Alcoa® ULT36x, 22.5” x 8.25” wheel, and Alcoa® ULA18x 22.5″ x 8.25″ Wheel. This revolutionary development holds immense promise for improved efficiency and sustainability in the trucking sector.

Enhanced efficiency with the lightest aluminium truck wheel

A standout achievement of the Alcoa ULT36x wheel lies in its lightweight design, which employs advanced materials and an innovative hand-hole-free structure. These wheels offer a significant reduction in weight without compromising performance. This breakthrough translates into higher efficiency and cost savings for trucking companies, as the increased payload capacity allows for optimized operations, reduced fuel consumption, and decreased carbon emissions.

The Alcoa® ULT36x wheel is 1.6 kg lighter than its predecessor, weighing just 16.3 kg. It is equipped with proprietary Magna Force® alloy, 17% stronger than the industry standard and has played a critical role in developing the ULT36x. Commercial fleet operators can achieve maximum efficiency and profitability with the ULT36x wheel, even in tough conditions.

Some of the highlights of the new wheel include:

- Savings of up to 2L of fuel per 1,000 km when converting from steel to aluminium on all positions

- Exceptional strength with a 3,355kg. load rating

- Alcoa® advanced finishes LvL One® and Mirror Polish

- Exclusive Alcoa® Dura-Bright® and Dura-Black™ surface treatments

- Patent-pending wheel design – No hand holes, impact tested and designed for strength

- Maintenance friendly valve system: two 25mm valve access holes for dual mounting, and dual inflation

- Works with ATIS and Halo systems

- brings both inner and outer dual valve into wheel well for easy access

Innovation is the key

Innovation remains a driving force within the trucking industry, as demonstrated by the introduction of the Alcoa ULT36x wheel. Technological advancements play a pivotal role in improving safety and efficiency. By embracing these innovations, the industry exemplifies its commitment to continuous improvement.

The Alcoa ULT36x wheel also incorporates the company’s vHub™ Bore Technology, which reduces hub-to-wheel contact area by up to 64% compared to other aluminum wheels, minimizing surface area for corrosion to form.

Advance Surface treatment

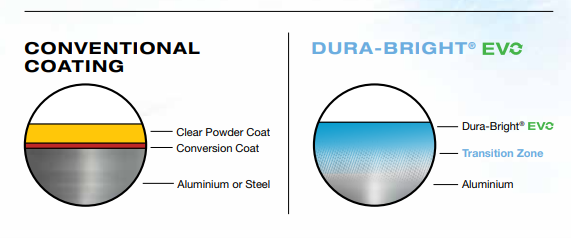

ULT36x will be available with Alcoa Dura-Bright® Wheels surface treatment, which acts like a force field around your wheels that repels dirt. So, when it’s time to clean, a simple soap and water wash gets you back on the road. No more polishing. Less time washing, more time driving.

Alcoa Dura-Bright® Wheels are manufactured using proprietary technology and production processes specifically tailored to achieve superior aesthetics, easy maintenance, and durability. Alcoa Dura-Bright® surface treatment penetrates the aluminium, forming a molecular bond that becomes part of the wheel itself. That means it will not crack, peel, or corrode like coated wheels, looking newer for longer.

These advancements showcased in the trucking industry signify a brighter and more prosperous future. The Alcoa ULT36x wheel marks a significant milestone in efficiency, sustainability, and safety. As the industry embraces these innovations, we can expect continued progress and collaboration in the sector.

For more information about the world’s lightest and strongest heavy-duty truck wheels, contact Howmet Wheel Systems at 1800 955 191, email alcoawheels.sales@howmet.com, or visit alcoawheels.com.au. Stay updated by following Alcoa on: alcoawheelsaustralia