Alcoa Dura-Bright® wheels are best known for their slogan, NO MORE POLISHING, because they are designed to lower maintenance costs with a patented surface treatment that penetrates the aluminium of the wheel, forming a molecular bond that becomes an integral part of the wheel.

This provides a protective shield against cracking, peeling and filiform corrosion, all the while keeping their shine and looking newer for longer, even after hundreds of washes* and thousands of kilometers.

To get the best return on investment, we recommend regular cleaning to the Alcoa Wheels specifications, along with following our top 3 tips for prolonging the life of your Dura-Bright® wheels.

MAKE SURE YOU ARE CLEANING THEM TO THE ALCOA WHEELS RECOMMENDATIONS

We recommend that, just as you would care for any treated wheel, you consider the following when performing your regular cleaning of Dura-Bright® wheels:

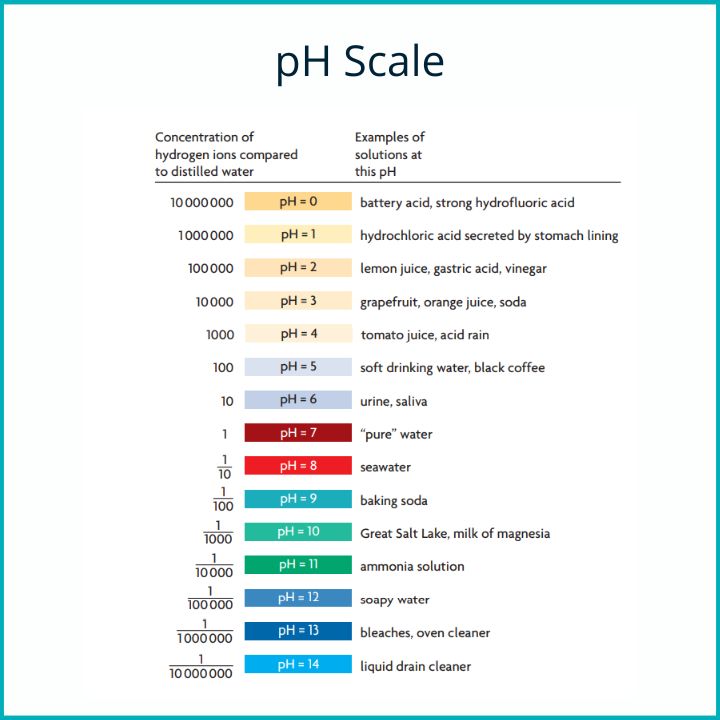

- Be aware of the pH of the cleaner (refer to point 1 below),

- Check the chemical composition of the cleaner read the MSDS to ensure there are no harsh chemicals in there such as ammonia, bleach, or sodium hydroxide,

- Make sure you watch the time for which the chemical is on the surface of the wheel,

- Follow the Alcoa® Dura-Bright® Wheels Cleaning Process (this is equally important as the factors above)

1. Avoid Abrasive Cleaners, Compounds and Tools

While Dura-Bright® wheels are three times more resistant to harsh chemicals and 10 times more resistant to corrosion** caused by road salts and weather elements, they still needed to be regularly cleaned as per Alcoa Wheels recommendations.

Dura-Bright® wheels are designed to be more hydrofluoric acid resistant than coated aluminium wheels.

Their chemical resistance sits in the pH range of 2-12, so we recommend making sure you are not cleaning with a cleaner that’s too high in pH.

Q: What about the detergents being used to clean my truck and trailer? Will they affect my wheels?

A: The detergents that you clean your Truck and Trailer with should be fine to wash your wheels with. If you do use a high pH level cleaner to remove stubborn dirt and grime wash off immediately and do not allow to sit on the wheels.

Abrasive tools can still damage the durable surface of a Dura-Bright® wheel, and if corrosion happens to form due to the surface being scratched, you will void your Alcoa Wheels warranty.

2. Keep Brake Dust from Becoming Encrusted

The Alcoa Wheels warranty does not extend to Dura-Bright® wheels that have not been maintained frequently or that show encrusted brake dust.

3. Make Sure Contact with Other Wheel Components is Reduced

Corrosion and or discolouring of your Dura-Bright® wheels can occur as a result of making contact with other wheels, hubs, drums, wheel nuts, nut covers, and hub covers, as mentioned above.

Ensure that these are regularly checked and remedied before damage occurs, as this is not covered by your Alcoa Dura-Bright® Warranty.

WHAT IS COVERED BY YOUR DURA-BRIGHT WHEELS WARRANTY?

Dura-Bright® surface treated wheels are warranted against:

- Filiform corrosion (worm or hair like lines, generally milky in appearance, underneath the surface protective treatment and emanating from damage to the surface treatment such as scratches or damage from mounting hardware or balancing weights)

- Blistering due to loss of adhesion of the surface treatment

- Lift off of the surface treatment due to physical damage

WHAT TO DO ABOUT SCRATCHES

It is natural that at some time during the service life of Dura-Bright® wheels, they might become scratched or damaged by road debris and/or mechanical damage.

If scratches or other damages occur to the Dura-Bright® treatment that expose the aluminium underneath, the exposed metal may naturally oxidize, but any corrosion will be limited to the exposed metal and will not extend into or underneath the Dura-Bright® treatment.

Continue to follow the recommended washing and cleaning instructions.

The mounting area can become scratched or discoloured when mounted against another wheel, hub or drum.

Similar scratches can be caused by contact with wheel nuts, nut covers, and hub covers, so keep on top of that.

WHAT TO DO ABOUT DULL APPEARANCE

We have found some customers report that over a period of time Alcoa Dura-Bright® wheels will become dull. This is due to a constant wash with soap and water.

To resolve this issue, dry your wheels off either with a soft cloth or chamois whenever you wash them.

This will help them keep their shine.

Alcoa Dura-Bright® wheels are designed for low maintenance, which means less time and money spent on cleaning.

By following the recommendations above, you will prolong the life of your Dura-Bright® wheels and avoid costly maintenance issues or replacements.

Make Sure It’s An Alcoa® Wheel

To spec your wheels, ring ![]() 1800 955 191 to talk with our wheel experts, or fill out a contact form and we will reach out to you to answer your questions and discuss your specifications.

1800 955 191 to talk with our wheel experts, or fill out a contact form and we will reach out to you to answer your questions and discuss your specifications.

* Dura-Bright® wheels should be cleaned in accordance with the Alcoa® Dura-Bright® Cleaning Guide.

** After undergoing a 240 hours of CASS (Copper Accelerated Acetic Acid Salt Spray) tests