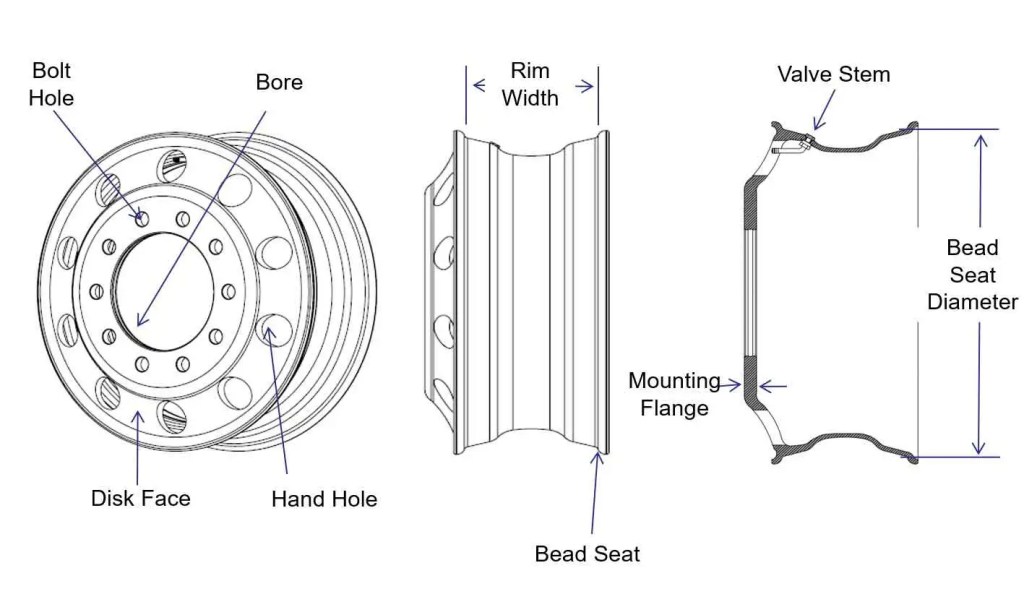

Alcoa® wheels come in different shapes, sizes and looks. The diagrams below illustrate the typical truck wheels features, which include:

- A bore used to attach to the axle of the vehicle.

- Bolt holes used to assemble the wheels onto the vehicle.

- Hand holes, which allow heat dissipation as the vehicle drives on the road.

- The flat side of the wheel called disk face encompasses a mounting flange that not only gives the wheel its aesthetics, but more importantly provides the robustness of the wheel.

- Bead seat, which is a critical surface as it is the interface to the tire. The bead seat of the wheel is the flat area around the wheel, just inside of the flanges, where the edges of the tire “seat” onto the wheel. The bead seat can affect how the tires seal. Any major imperfection, such as a bend in the wheel, will transfer vibration from the wheel/tyre combination directly into the suspension and can make the vehicle shake at speed.

- The rim width and bead seat diameter specify the size of the tire to mount on the wheel.

- Depending on the application, the flange thickness can vary to ensure it meets the design and application intent.

- Alcoa® medium and heavy-duty wheels are produced and assembled with valve stems. The valve stem is the universal mechanism used to inflate or deflate the tire. The Alcoa® wheels portfolio includes two wheels that have dual valve stems. With a second valve stem mounted at 180 degrees, the tire pressure monitoring system (TPMS) sensor can operate on one valve while air pressure is serviced on the other.

Typical Wheel Assembly Configuration

While all wheels and tyres appear to be alike, round and somewhat simple, they are quite complex. Countless items need transportation, and each scenario demands its own tailored solution.

- The wheel connects the tyre to the axle of the vehicle. It transmits forces from the axle to the tyre and vice versa. The wheel carries the vehicle, as well as the load in it. Furthermore, as the wheels connect to the axle, they enable the vehicle to accelerate and decelerate.

- The tyre contains the air and therefore allows for a comfortable ride. It also provides the vehicle the ability to handle speed and traction during maneuvering, and provides the ability for braking.

Now that we have defined the basic purpose of a wheel and a tyre, let’s keep reviewed truck wheels features their practical application.

Front Wheel Assembly

The automotive wheel/tyre application is somewhat straight forward, as there are two tyres per axle; one on each side.

In medium duty and heavy-duty applications, there are many variations. Mount the front tyre assembly on either side of the truck axle through a hub, utilizing the mounting holes. The number of holes can range from as few as six to as many as 10, depending on the wheel design and application. As such, the hub is the intermediate component that attaches to both the wheel and the axle, allowing the tyre to rotate freely.

Rear Wheel Assembly and Wide Base Assembly

In medium and heavy-duty applications, refer to the rear wheel assemblies as “duallies,” assembling them face to face in pairs on each side of the rear axles. Weight-sensitive scenarios allow for the replacement of two duallies or duallable wheels with a single wide-base wheel, offering substantial weight savings to the customer. In both cases, mount the wheels onto the axles’ hubs using two different methods.

Offset Overview

In the assembly process, mount the wheel flush to the hub. The term “offset” refers to the distance between the flush wheel surface and the wheel’s center

- In the front assembly, name the offset “inset” as the hub is mounted flush against the inner face of the wheel flange. Likewise, the outset is the distance between the middle of the rim and the outside face of the flange.

- In the rear assembly, where duallies are the norm, designate the distance between the two midpoints of the wheels as “dual spacing”

- When employing a wide base instead of two duallies in the rear assembly, the offset may be positive, negative, or zero, depending on the hub-flange position in relation to the wheel’s center.

No that you know all about truck wheels features, Make Sure It’s An Alcoa® Wheel

To spec your wheels, ring ![]() 1800 955 191 to talk with our wheel experts, or fill out a contact form and we will reach out to you to answer your questions and discuss your specifications

1800 955 191 to talk with our wheel experts, or fill out a contact form and we will reach out to you to answer your questions and discuss your specifications