Quick Reference Guide

Choosing the right wheel starts with a clear advantage.

- Industry best five-year limited warranty for additional peace of mind

- One-piece forged aluminum strength that is 5x stronger than steel

- Reduce maintenance and increase safety

- Run cooler to extend tire and brake life

Advanced Finishes

Mirror Polish

- The premium wheel with highest level of gloss and reflectivity on the market

- Designated by 1, 2, or 3 in part number

- Part Number Example: 882673

LvL ONE®

- Its reflective finish and high gloss levels give the wheel an appearance that redefines the standard in wheel finishes

- Designated by 7 or 8 in the part number

- Formerly known as: Clean Buff, Standard LVL ONE® Bright or Level ONE

- Part Number Example: ULT397

Brush Finish

- Bright, non-reflective surface on both sides

- Designated by 0 or 9 in part number

- Only offered with Dura-Bright® Surface treatment

- Part Number Example: ULT390DB

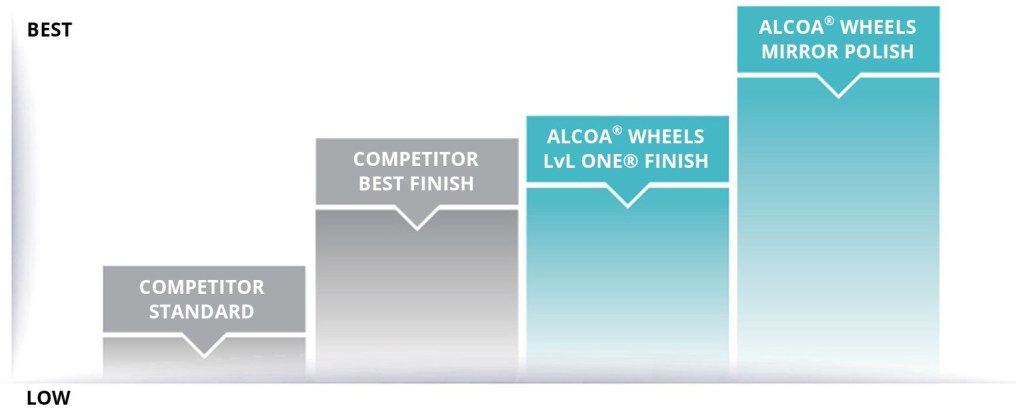

See How Alcoa® Wheels Advanced Finishes Stacks Up Against Our Competitors.

REFLECTIVE CLARITY COMPARISON

Competitor Standard

Competitor Best

Alcoa® Wheels LvL ONE®

Alcoa® Wheels Mirror Polish

Finish Quality Chart

Surface Treatments

Dura-Bright®

- Surface that cleans easily with soap and water without the need to polish

- No cracking, peeling or corrosion

- Designated by a DB after the finish option

- Part Number Example: ULT391DB

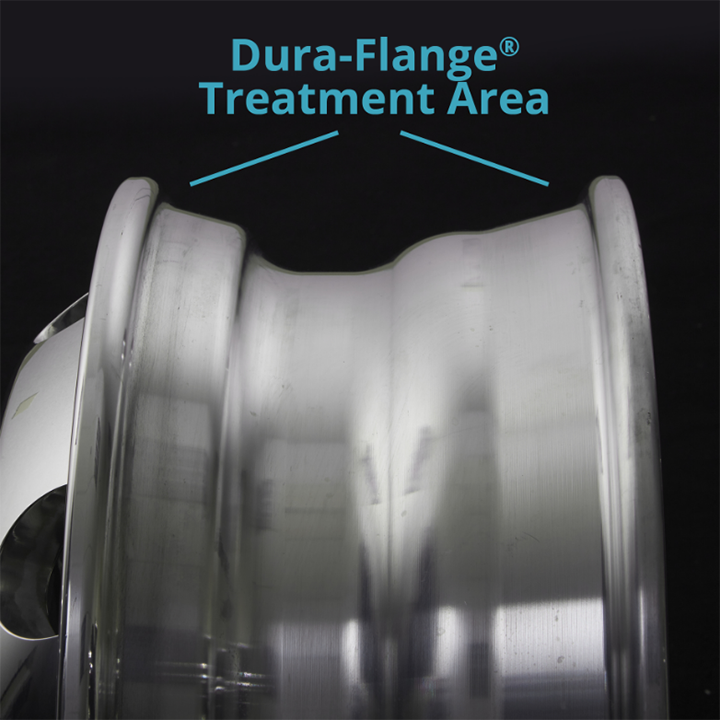

Dura-Flange® Wear Protection

- Rim-flange treatment that minimizes flange wear

- Best for logging, tankers, city buses, motor coaches, or any application involving shifting loads

- Designated by a DF after the finish option

- Part Number Example: 882677DF

Dura-Bright® + Dura-Flange®

- Both Dura-Bright® and Dura-Flange® on the same wheel, and most importantly, maximum protection

- Designated by a DD after the finish option

- Part Number Example: 882671DD

Dura-Black™

- Same benefits of all lightweight Alcoa aluminum wheels, now in Menacing Matte Black

- Designated by a BLK after the finish option

- Part Number Example: ULT39BLK

What’s New

Productivity has reached a new level with the new vHub™ Bore Technology. The vHub™ Bore Technology reduces hub-to-wheel contact area by up to 64% versus other aluminum wheels on the market, leaving less surface area for corrosion to form.

Lightweight Solutions

We know a lighter wheel leads to greater productivity through increased payload, improved fuel efficiency and enhanced sustainability.