Alcoa® forged aluminum wheels lead the industry for many reasons, including their high quality. Therefore, it’s critical to understand what indicates not only a high-quality aluminum wheel, but an Alcoa® forged aluminum wheel. One example that suppliers use to identify a quality wheel is the presence of a roll stamp. The Alcoa® roll stamp serves as a clear reassurance that your wheel is authentic. In addition, the roll stamp contains important wheel identification information that contributes to the safe operation of your equipment, through proper maintenance and wheel service under the manufacturer’s guidelines.

When did Alcoa® Wheels begin to apply the roll stamp?

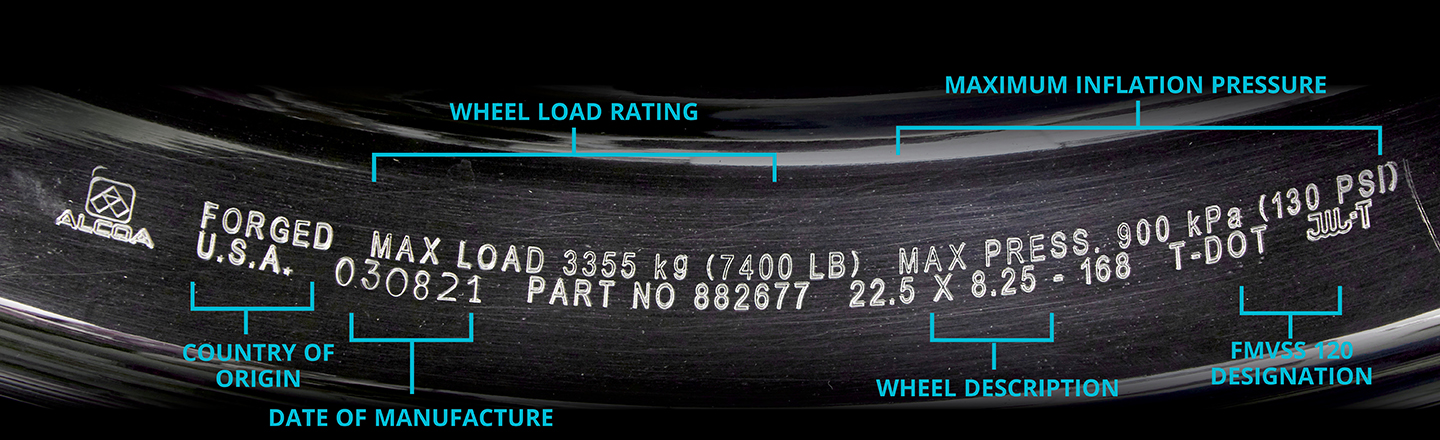

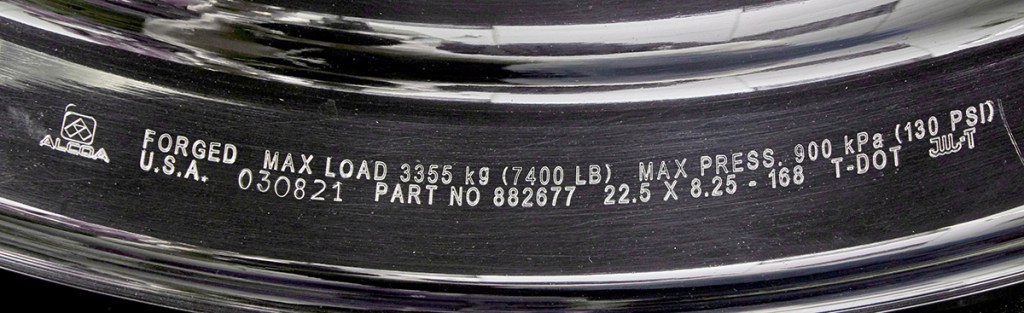

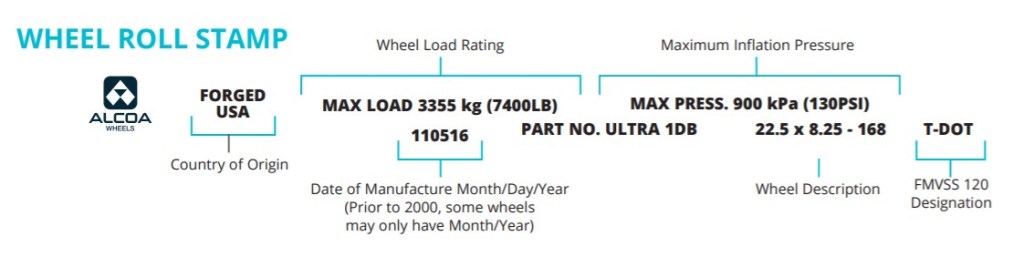

Since 1977, all Alcoa® forged aluminum disc wheels have been identified with a stamping that showcases the wheel load rating, maximum inflation pressure, date of manufacture, part number, wheel description and Department Of Transportation (DOT) marking designation. See Figure 1.

Figure 1: Roll Stamp

Prior to June 1996, all Alcoa® heavy duty truck forged aluminum wheels had the Alcoa® identification symbol on the outside of the disc near the handhole, and in-line with the valve location. This type of marking was ultimately phased out on all heavy-duty truck wheels manufactured after June 1996.

Where is the Alcoa® roll stamp located?

Alcoa® wheel identification is located 180 degrees from the valve stem on the open side of the wheel. Wheel identification required by the DOT must be legible. Wheels should immediately be removed from service if this identification is not legible, and then scrapped.

What information does the roll stamp display?

- Country of origin. All Alcoa® wheels are manufactured in the United States, Hungary or Mexico under stringent manufacturing guidelines. These guidelines have been trusted since 1948. Quality control checks are also regularly conducted.

- Wheel load rating. This information is critical for driver and passenger safety, as well as wheel/tire longevity.

- Date of manufacture. The manufacturing date allows tracking and monitoring of the product warranty.

- Maximum cold inflation pressure.

- Part number.

The part number typically consists of 6 digits and may be followed by two characters. The first five digits represent the wheel family, while the sixth digit indicates the wheel finish. The seventh and eighth characters indicate the surface treatment of the wheel, if applicable. Example part number: 885651DB. This denotes an 88565 wheel family with a Mirror Polish Outside Only and Dura-Bright® Surface Treatment. Read the article HOW TO READ PART NUMBERS. - Wheel size. Identifying the size of the wheel prevents installing incorrect wheel sizes. Alcoa’s technical staff can assist in advising on the correct wheel specs for your vehicle.

- T-DOT certification. The DOT marking indicates that the wheel is manufactured according to the DOT specifications. Letter “T” identifies the association that is dictating the rim profile. In this case, “T” is the Tire Rim Association. Alcoa® wheels may have additional markings in the roll stamp to designate certification in other regions. See the Alcoa® Wheels Service Manual Section 3-12 Identification for more information.

MORE RESOURCES:

Watch Video: About the Roll Stamp and the Heat Indicator Label